Characteristics

The regenerative radiant tube burner alternately sends combustion air to two regenerator-equipped burners and recovers exhaust heat by using the companion burner. Since this recovered heat is reused as high-temperature preheat air, this burner can realize substantial energy saving.

Specifications / Shape dimension

| Fuel | Fuel Gases |

| Standard Pressure | Gas 10kPa、Air 10kPa |

| Flame Safeguard System | UV Phototube |

| Type | Capacity kW (×103 kcal/h) |

Radiant tube | Connection | |||

| Main Air |

Main Gas | Hold Air |

Exhaust port | |||

| RSTB-125 | 58(50) | 125A | 80A(JIS5K) | Rc 3/4 | Rc 1/2 | 80A(JIS5K) |

| RSTB-150 | 93(80) | 150A | ||||

| Type | A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | Mass (kg) |

| RSTB-125 | 318 | 127 | 127 | 45 | 84 | 572 | 683 | 1255 | 55 | 300 | 92 | 200 | 145 | 185 | 335 | 377 | 82 |

| RSTB-150 | 330 | 118 | 230 | 200 | 365 | 407 | 96 |

Download of DXF data

※ Download procedure

- Put the cursor on the model designation of the outline drawing you want to download, and click the right button of the mouse.

- Select “Save Target As (A)” on the menu.

- Select a location to save, and click “Save.”

※ Some security software does not permit downloading. If that happens, set the securities to “OFF” before downloading.

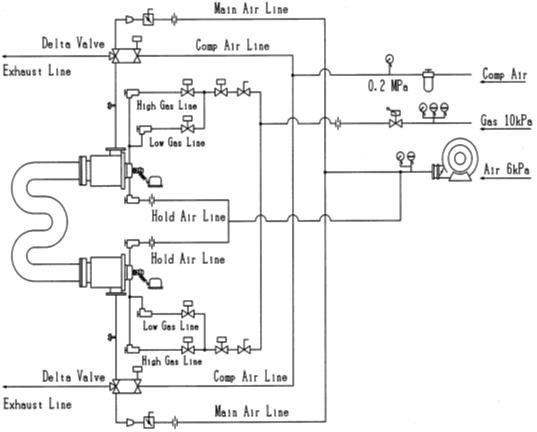

Flow sheet

Technical data

- Ceramic Ball Replacement

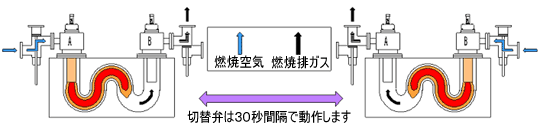

- Flow of combustion air and exhaust by selector valve operation

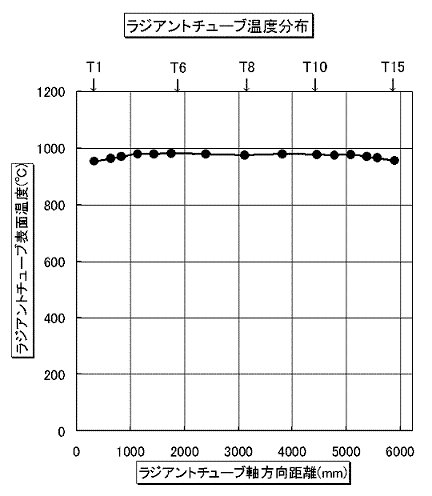

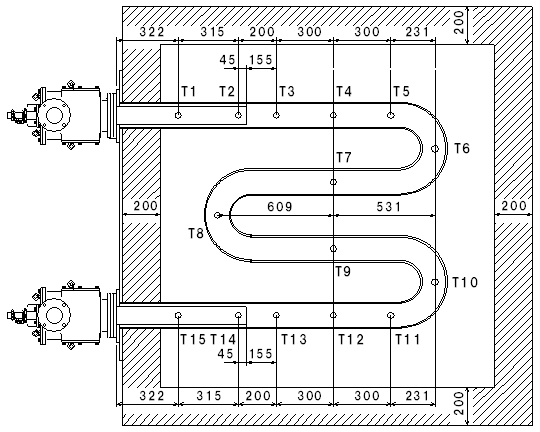

- 150a W Tube surface temperature distribution (furnace temperature 950°C)

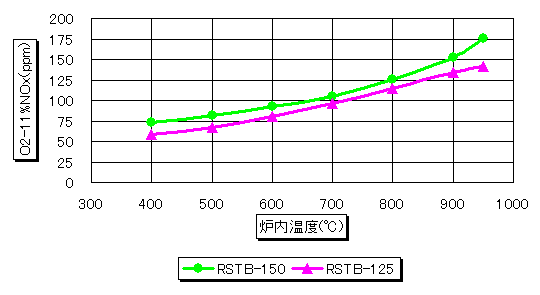

- Furnace temperature and NOx characteristics

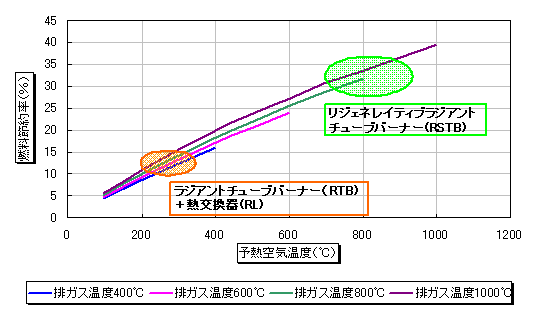

- Preheat air temperature and fuel saving rate

- Exhaust temperature and thermal efficiency for furnace temperature (exhaust loss basis)

1. Ceramic Ball Replacement

2. Flow of combustion air and exhaust by selector valve operation

3. 150a W Tube surface temperature distribution (furnace temperature 950°C)

4. Furnace temperature and NOx characteristics

5.Preheat air temperature and fuel saving rate

6.Exhaust temperature and thermal efficiency for furnace temperature (exhaust loss basis)